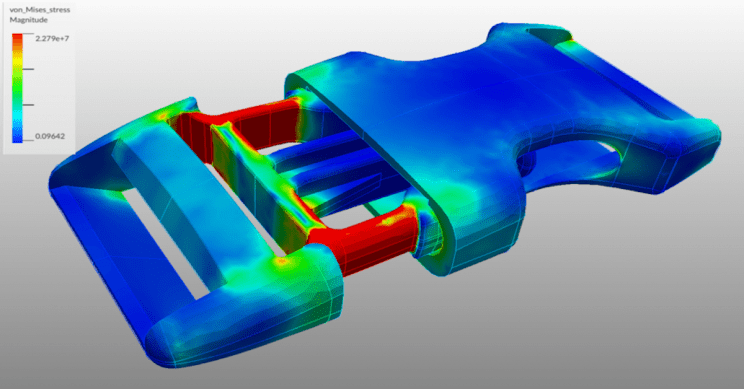

Structural Analysis

Mechanical elements used in real life; material conditions, fasteners, assembly errors, applied loads, etc. It tends to show nonlinear behavior for reasons. As Cosmos, we carry out structural analysis activities of mechanical parts. In this way, before the parts are produced, the relevant analyzes are performed and the errors in the parts are detected and the 3D geometry is adjusted. Using the finite element analysis method, possible deformations and stress values are determined based on dynamic and static loads. Thus, constraints on the previously determined geometric design are determined and parts are optimized.

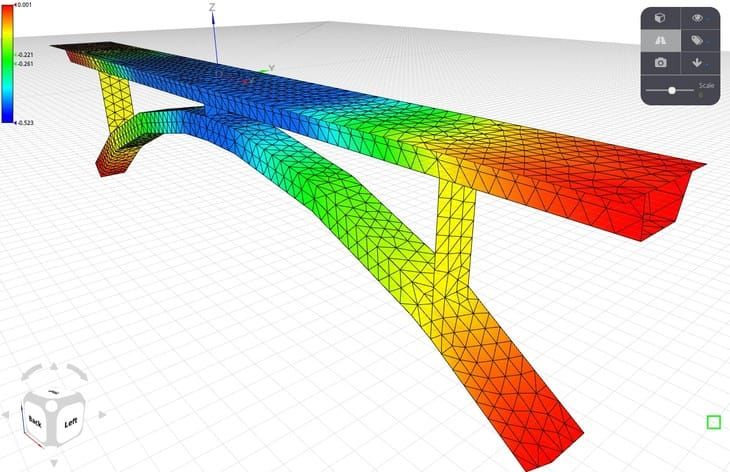

Buckling Analysis

Generally, buckling is seen in structures with elongated geometries. For structures that may be critical in terms of buckling, not only static analysis should be performed, but also whether the structure is safe against buckling should be verified by buckling analysis. Damage to structures can be caused by buckling and plastic deformation. Euler calculation method gives very good results in case of damage only due to buckling below the yield strength of the structure.

In some cases, buckling and plastic deformation can be seen together. In such cases, performing nonlinear analyzes is necessary to more accurately model the behavior of the structure.

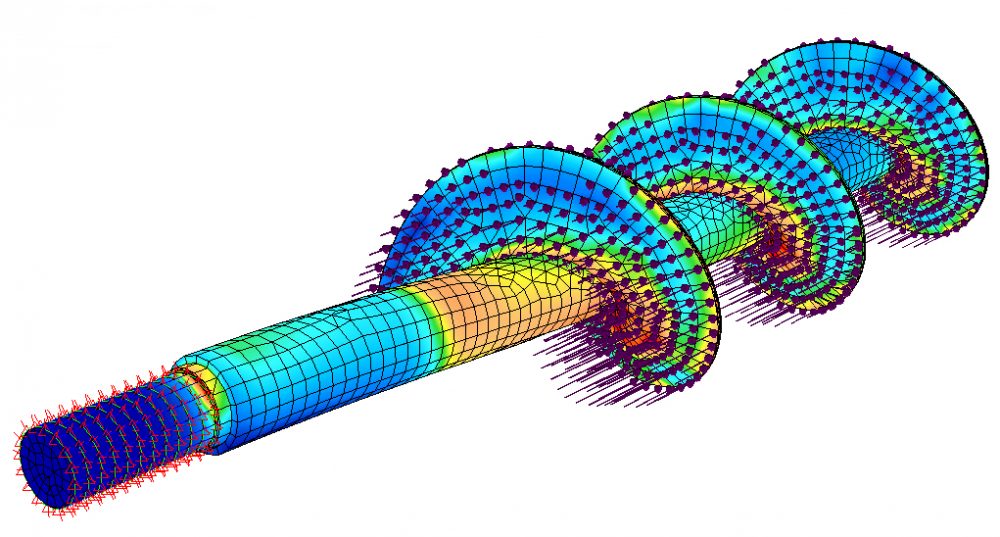

Modal Analysis

In modal analysis, it is aimed to calculate the dynamic stability of the systems by reaching the natural operating frequency values of the structure.

Analysis of signals is generally based on the Fourier analysis. The resulting transfer function will exhibit one or more resonances whose characteristic mass, frequency, and damping rate can be estimated from the measurements.

Studies can be carried out to keep these values at optimum levels.

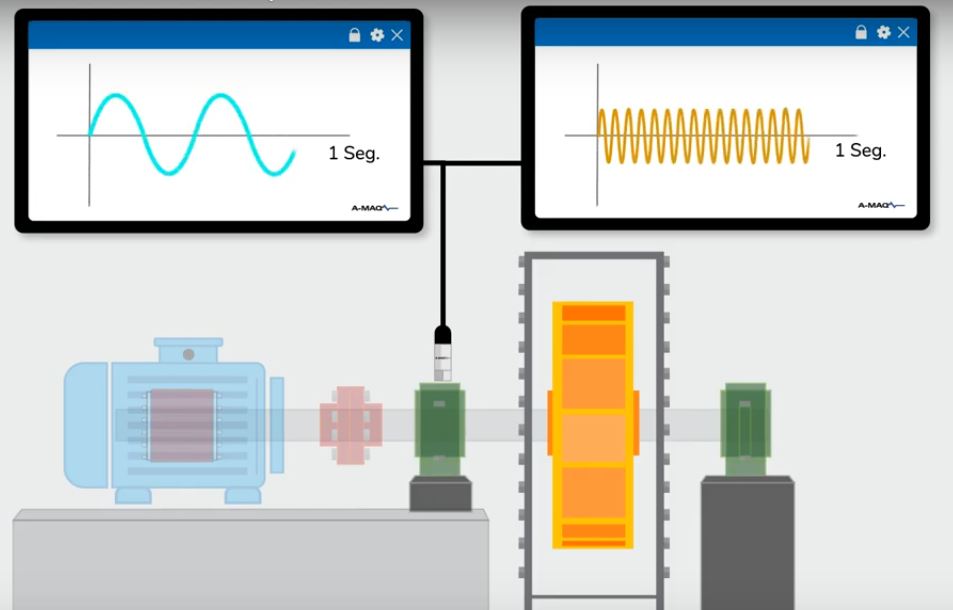

Vibration Analysis

Vibration is the reactive behavior of a machine element against internal and external forces within the mechanical part. Vibration signals produce a complex waveform due to the action of different forces. As Cosmos, we perform deformation and strength analyzes effected by non-linear (non-linear) loads, based on frequency and amplitude parameters during vibration analysis.

Fatigue Analysis

Fatigue analysis enables designers to predict the fatigue life of new products such as automobiles, aircraft, heavy equipment, electric motors and electronic components. The analysis yields data on crack propagation and strength that you can use to make informed choices to ensure product integrity and optimize fatigue life, thus preventing premature product damage to the part in use.

We can apply fatigue analysis to determine why an existing product is failing, so we can safely redesign your product and avoid unexpected damage.

Thermal Analysis

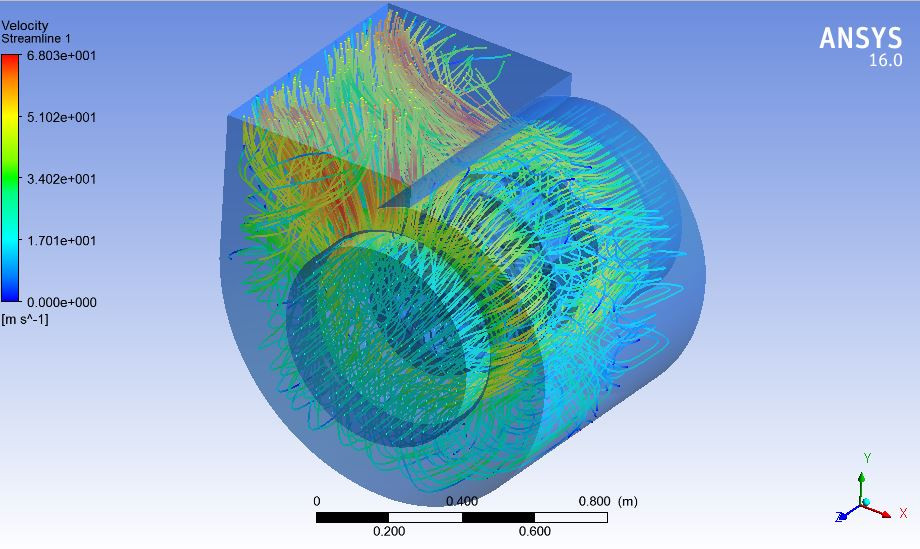

We carry out activities on detailed thermal analysis services to investigate and solve the problems caused by heat transfer. We understand the thermal properties and actions of liquids and gases and their contribution to the effects caused by convection, conduction and radiation, and support the development of products with innovative design validation processes.

Flow Analysis